Some products we can only make from birch plywood, some only from solid wood (usually oak), and some from both. The difference between them is about as different as an apple and an orange. The issue is not only the color, but also the details.

First a few words about birch plywood, why and for what we choose it. Top grade birch plywood is a beautiful material that is 100% natural. Due to the fact that it is made like a millefeuille cake, from several layers of solid birch wood, we get a continuous wood pattern throughout the sheet.The layers are glued under high pressure and each layer has a direction of wood fibers perpendicular to the neighboring layer that makes it possible to produce durable products of very small thickness. Also when the humidity changes, from the previous winter to the next winter, the width (across the fibers) of the material remains almost unchanged. But the ultimate dimensions of a single piece cannot be larger than the size of a sheet of plywood. And the ends are always striped – the transverse cut on birch is always darker than the longitudinal one. And always, after any sanding, a slight roughness is formed on the ends over time.

Changes in weather, in humidity, for wood products make a huge difference – just think of a door whose width changes throughout the year. To demonstrate this we took bars of oak and ash, measured their dimensions, and tested those dimensions in different weather conditions for several years in a row.

In summer and winter, outside, in the room and in the shower cabin. And we know from our own experience that oak lying in wet snow in the rain at a temperature of 2C and humidity of 94% across the fibers (board width) will be about 1.4% wider than in dry and warm weather. And there is almost no change in length. At a door width of 800mm. that 1.4% would be 11mm – less than 1/2 inch, but still a lot. Ash, under the same conditions, will change in both length and width. In width (across the fibers), by about 2.17%, that is a 17.3mm. change in width for the same door. In order to keep the door from jamming in wet weather, in dry weather we have to put up with an inch wide gap? No, they’ve come up with a fielded panel construction. In the example of a door – it is a frame consisting of left and right vertical posts, wood fibers along the long side and several horizontal bars (wood fibers along the long side of the bar, respectively perpendicular to the vertical posts). Yes, the fielded panel changes its dimensions in width as the weather changes, but the frame elements provide opportunities for it to move in specially designed slots as it changes dimensions.

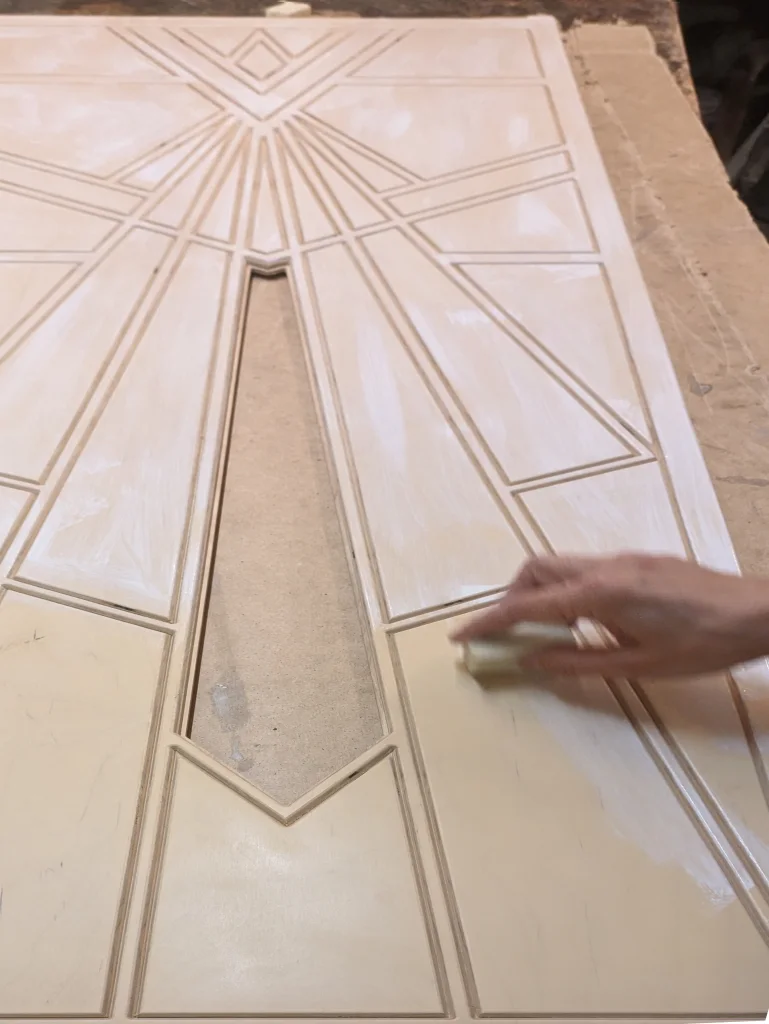

From a construction point of view, of course, any product is easier to make from a single piece. This is possible with plywood. On the example of any door it is clear that the door made from plywood can consist of one part, and from solid wood (oak) – already at least five. But it is not possible to make a door from plywood because of the limitations on the length of one part. Consequently, only solid wood is suitable and from the same minimum of five parts. And all these five parts must be connected in such a way that over the years and even after decades these connections do not… sag like the skin on our cheeks sags over time. A hundred years ago this was impossible – modern glues had not yet been invented and there were no proper tools for cutting wood. Wood used to be joined with bone-based glue, which would now be called “biodegradable”, that decomposes over the years. Now we at A&D use modern adhesives that don’t degrade over time and use a special form of wood joints designed with the fact that wood shrivels over time – as it shrivels, our joints will strengthen themselves and even if the PVA glue we use doesn’t last forever, the parts will peel themselves even without glue. As the wood shrivels in width, it will squeeze the cross pieces tighter and tighter –

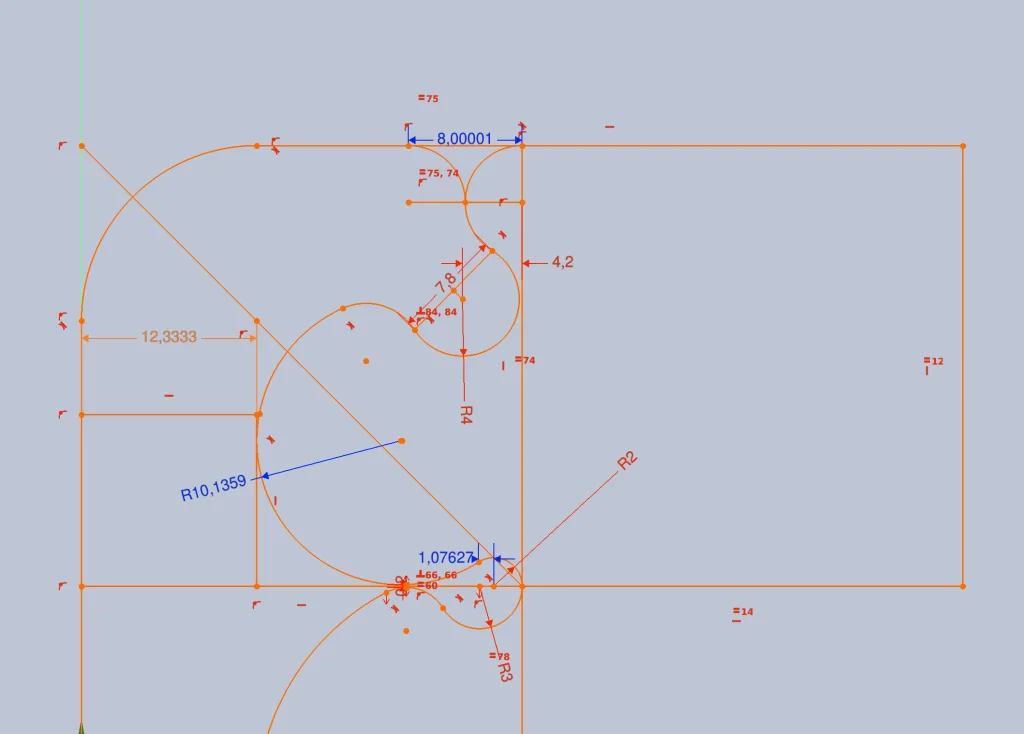

You can’t tell from the photo how much engineering trickery is in these simple curves. But here’s the blueprint–

Every bend makes a difference. While plywood has the same strength across height and width, solid wood of any wood species is brittle across the fibers. Almost like glass. If you hit the middle of the board, it will break and the break line will run along the fibers – that’s the secret of the trick of movie strongmen breaking boards with a blow of their hand. This will not happen with plywood. That’s why a screen door made of plywood Art Nouveau style wood folding screen inspired by Gaspar Homar and Charles Rennie Mackintosh consists of one piece, and one made of solid oak of eight – so that it doesn’t break.

Now we can talk about color. Birch plywood of the highest grade is made, understandably, from birch. And birch is beautiful not only for its durability, but also for its color – it is docile and easily takes the desired color. Oak is stubborn. Therefore, processing with the same oil of oak and plywood gives a completely different result – the red of oak is not as red as that of birch (plywood) and the yellow will never be straw-yellow but rather brown. Moreover, every millimeter of solid oak has a different color and pattern than the previous one. Here is an example, hinge elements cut in succession from the same board with a minimum distance: you can see that even in 20mm the color changes from dark to light and again from light to dark – the color of the hinge elements is not the same as the previous one –

Changing the angle, the side from which we look at an object, greatly affects the perception of color-

Another example: the one on the right is made of solid oak wood Art Nouveau style handmade wood folding screen “Lemon tree” inspired by Gaspar Homar, and the one on the left is made of birch plywood.Art Nouveau style wood folding screen inspired by Gaspar Homar and Charles Rennie Mackintosh. Both products are treated with the same oil. And the color is somewhere the same, and somewhere completely different. The differences can be seen especially clearly on the parts of the wood treated with oil without dyes –

Speaking of birch’s docility and oak’s stubbornness, let’s also talk about white color – no matter how hard you try, you can’t make oak white. Unless you treat it with chlorine. Paint it with paint – yes, you can, but then what’s the point? After all, the paint completely hides the texture of the wood, the pattern of its fibers. So if you need to make an object white, your choice is only birch, only plywood –

The conclusions are simple – nothing is the same. Using birch plywood gives a more “even” and predictable color result, it is easier and cheaper. Using solid oak gives a less predictable result, but luxurious.